Basic Parameters

Bearing SI25 T/K belongs to rod end bearingm series. It is the crystallization of our years of experience and advanced technology in the field of bearing manufacturing. While ensuring high precision and high reliability, this bearing can meet the usage needs under different working conditions and provide stable and lasting support for your mechanical equipment.

Product Feature

Product FeatureSize Specification

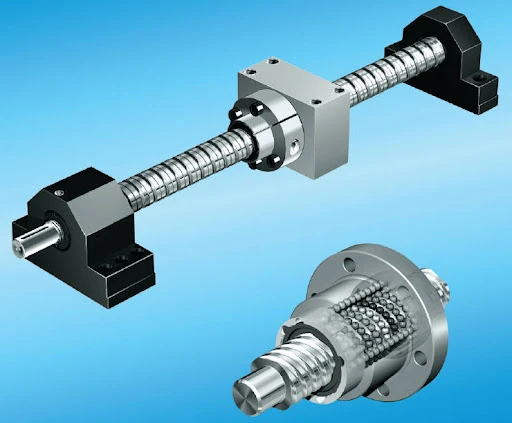

- The inner diameter of SI25 T/K is 25mm. This size enables it to fit various shaft components with a diameter of 25mm. The precise inner diameter size ensures a tight fit with the shaft, reducing gaps and looseness during installation, thereby ensuring the accuracy and stability of transmission.

Structural Design

- This bearing has unique advantages in structure. The letter "T" in the model reflects its special structural characteristics. For example, it may adopt [specific structural design, such as a special threaded connection method or internal structure]. This design enables the bearing to better adapt to [specific working conditions, such as different force directions or installation space limitations] during installation and use, improving the universality and applicability of the bearing.

High-Quality Materials

- We have selected high-quality [bearing materials, such as bearing steel] as the raw material for SI25 T/K. This material has excellent hardness, toughness, and wear resistance and can withstand a large [axial/radial] load. During long-term operation, it can effectively resist wear and fatigue and extend the service life of the bearing.

Precision Manufacturing

- During the manufacturing process, we strictly follow precision manufacturing processes. Each SI25 T/K bearing undergoes multiple processing steps, including [listing some key processes such as turning and grinding], and strict quality inspections are carried out after each step. This ensures that the bearing's dimensional accuracy, rotational accuracy, and surface quality all reach high standards and can operate stably in equipment with high-speed rotation and high-precision requirements.

Load-Carrying Capacity

- SI25 T/K has strong load-carrying capacity and can work stably within the specified range for both [axial/radial] loads. This makes it suitable for various mechanical transmission systems. For example, in [listing some application scenarios such as small industrial equipment and light machinery], it can reliably transmit power and ensure the normal operation of equipment.

Operational Stability

- Due to its precise size and excellent structural design, this bearing can maintain a low level of vibration and noise during operation. This is a very important characteristic for equipment with high requirements for operational stability, such as [relevant equipment types], and can effectively improve the overall performance of the equipment and the comfort of the working environment.

Unique Technical Features

- The "/K" in the model represents that this bearing has some special technical requirements or design features. For example, it may adopt [specific special designs such as special lubrication methods, sealing structures, or material treatment processes]. These special designs enable SI25 T/K to perform outstandingly under specific working conditions, such as [describing specific working conditions such as humid environments and high-temperature environments], and can effectively prevent [problems such as grease leakage and impurity entry], ensuring the long-term stable operation of the bearing.

Product Application

The bearing SI25 T/K is widely used in multiple industries, including but not limited to:

Industrial Automation

- On automated production lines, SI25 T/K can be used in various small robotic arms, conveying equipment, etc., providing reliable rotational support for their joint parts and ensuring the efficient and accurate operation of the production line.

Light Mechanical Equipment

- For light machine tools, printing equipment, packaging machinery, etc., this bearing can meet their requirements for precision and reliability, reduce equipment maintenance costs, and improve production efficiency.

Other Fields

- It can also be applied in other possible application fields such as [other possible application fields such as cooling fans for electronic equipment]. With its excellent performance, it provides a guarantee for the stable operation of equipment.

Product List

| Bearing No. |

Dimensions (mm) |

Basic Load Rating (N) |

Weight |

| ISO |

GOST |

d |

D |

B |

Dyn. C |

Stat. C0 |

(kg) |

| SI10 T/K |

SI10 T/K |

10 |

- |

14 |

14500 |

18000 |

0.077 |

| SI10-1 T/K |

SI10-1 T/K |

10 |

- |

14 |

14500 |

18000 |

0.077 |

| SI12 T/K |

SI12 T/K |

12 |

- |

16 |

17000 |

24000 |

0.100 |

| SI12-1 T/K |

SI12-1 T/K |

12 |

- |

16 |

17000 |

24000 |

0.100 |

| SI14 T/K |

SI14 T/K |

14 |

- |

19 |

24000 |

31000 |

0.160 |

| SI14-1 T/K |

SI14-1 T/K |

14 |

- |

19 |

24000 |

31000 |

0.160 |

| SI16 T/K |

SI16 T/K |

16 |

- |

21 |

28500 |

39000 |

0.220 |

| SI16-1 T/K |

SI16-1 T/K |

16 |

- |

21 |

28500 |

39000 |

0.220 |

| SI18 T/K |

SI18 T/K |

18 |

- |

23 |

42500 |

47500 |

0.320 |

| SI20 T/K |

SI20 T/K |

20 |

- |

25 |

42500 |

57000 |

0.420 |

| SI22 T/K |

SI22 T/K |

22 |

- |

28 |

57000 |

68000 |

0.540 |

| SI25 T/K |

SI25 T/K |

25 |

- |

31 |

68000 |

85000 |

0.720 |

| SI28 T/K |

SI28 T/K |

28 |

- |

35 |

86000 |

107000 |

0.820 |

| SI30 T/K |

SI30 T/K |

30 |

- |

37 |

88000 |

114000 |

1.100 |

| SI30-1 T/K |

SI30-1 T/K |

30 |

- |

37 |

88000 |

114000 |

1.100 |

| SI35 T/K |

SI35 T/K |

35 |

- |

43 |

94000 |

118000 |

1.600 |

| SI40 T/K |

SI40 T/K |

40 |

- |

49 |

100000 |

120000 |

2.400 |

| SI5 T/K |

SI5 T/K |

5 |

- |

8 |

5700 |

6000 |

0.016 |

| SI50 T/K |

SI50 T/K |

50 |

- |

60 |

112000 |

125000 |

5.000 |

| SI6 T/K |

SI6 T/K |

6 |

- |

9 |

7200 |

7650 |

0.022 |

| SI8 T/K |

SI8 T/K |

8 |

- |

12 |

11600 |

12900 |

0.047 |

Basic Parameters

Basic Parameters Product Feature

Product Feature Product Application

Product Application Product List

Product List